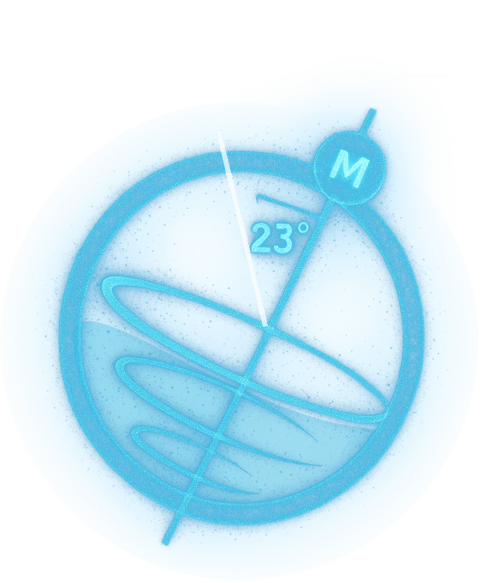

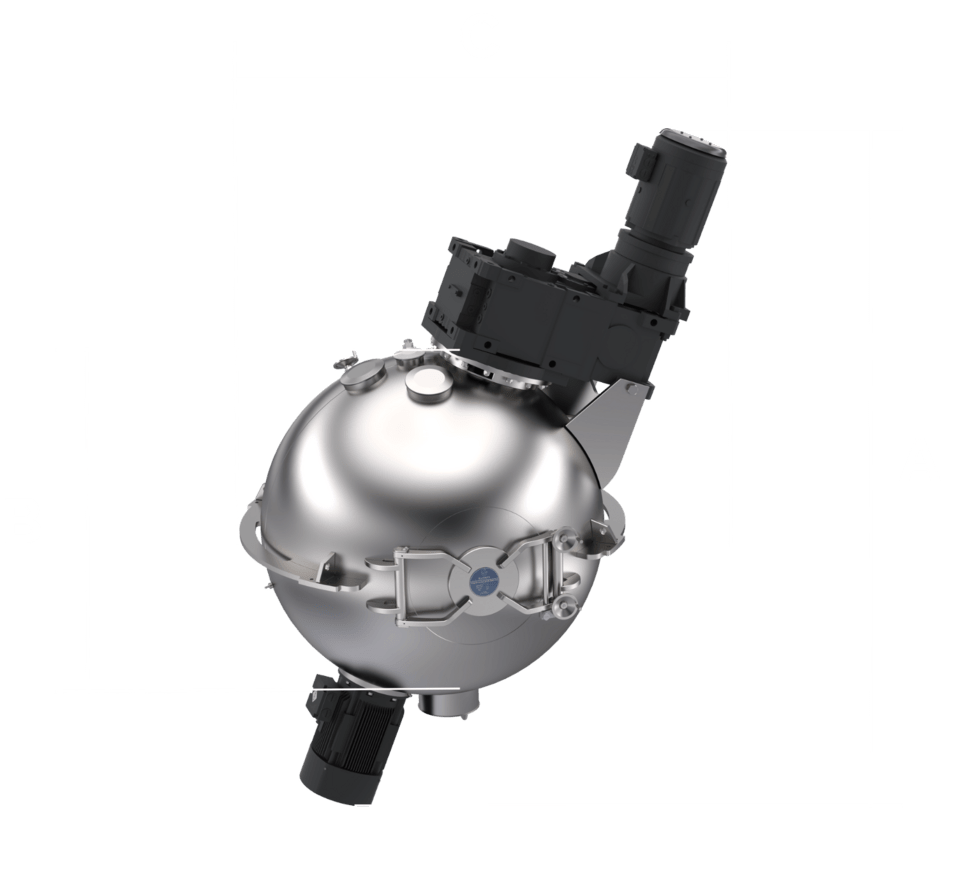

Inclined mixing chamber: The mixer's 23-degree incline, inspired by the Earth's axis, ensures optimal movement of the ingredients and significantly improves the homogeneity of the mixture.

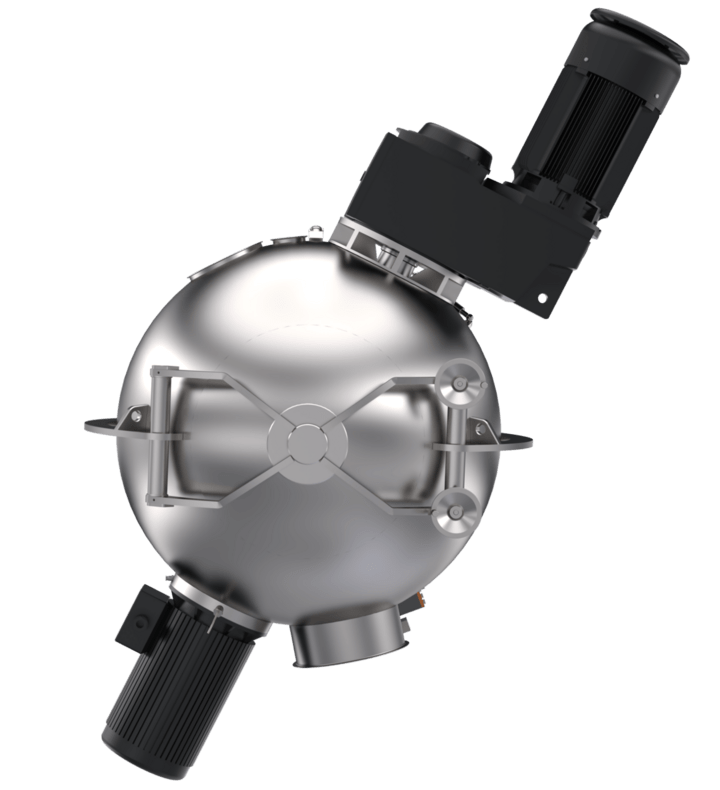

Spherical mixing chamber: The spherical design offers a reduced surface area, which minimises friction and enables shorter mixing times. This results in lower energy consumption and increases the efficiency of the mixing process.

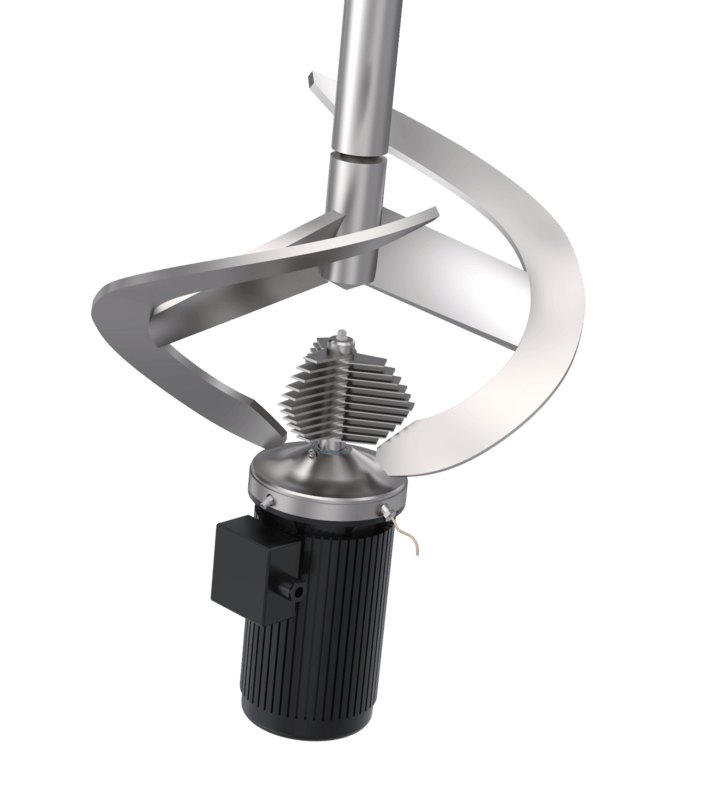

Gentle processing: The inclined and spherical mixing chamber ensures that ingredients are handled gently, preserving delicate flavours and nutrients. This is crucial for the quality of your products.

Versatility: The GloMix-Glaxiaris mixer is flexible in use and suitable for various industries.

Efficiency: Optimised mixing technology reduces mixing times and energy consumption. This results in faster production processes and lower operating costs.

Easy cleaning and maintenance: The mixer's design allows for quick and thorough cleaning. Smooth surfaces and a well-thought-out design ensure that no residues remain, guaranteeing the highest hygiene standards.