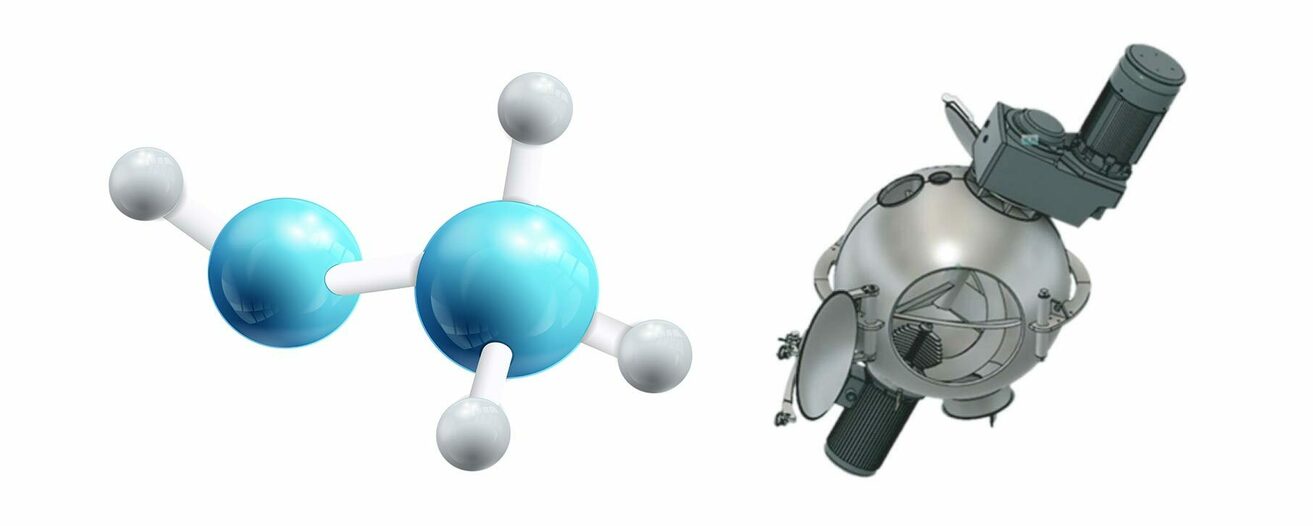

Since 2007, the company has focused on the research and development of fibre-reinforced composites. By reinforcing the material with various types of fibres, including high-performance carbon fibres, we can revolutionise the properties of the end product and significantly increase its strength. The manufacture of such products is complicated by the considerable variation in the weight characteristics of viscose fibres and polymers, as well as the different particle sizes of the components. This places high demands on the production equipment in order to achieve an ideal mixture.

Particular attention should be paid to composites for pipe production, which must be manufactured in emulsion media. Liquid peroxide and powdered polymer components must be combined at a specific temperature. Forced heating is required here. Wood-polymer composites, on the other hand, do not allow overheating during mixing and require the components to be kept cool. A number of composites are manufactured in a modified environment (vacuum, nitrogen, etc.). And some formulations contain additives that make up only a tenth of a percent of the mixture.

These diametrically opposed and specific conditions for the production of different compounds make production a high-tech process that requires competent selection of equipment and organisation of the workplace.

E.L.L. Germany is aware of the trends affecting society in general and every company in particular. Its goal is to integrate the environmental, social and economic aspects of sustainability into its business strategy. The development of technologies to increase efficiency, reduce costs and lessen environmental impact requires the use of short-term equipment. By focusing on cost savings and revolutionary solutions, E.L.L. Germany creates economic value along the entire value chain, from the idea to the implementation and introduction of a new product life cycle.